AGCO Power and Blue World Technologies have developed what they call a transformative solution: the methanol-powered fuel cell range extender for zero-emission agricultural machinery. With this advancement, the paradigm within sustainable farming equipment could be reshaped more drastically than many expect—potentially even surpassing initial industry forecasts concerning operational viability.

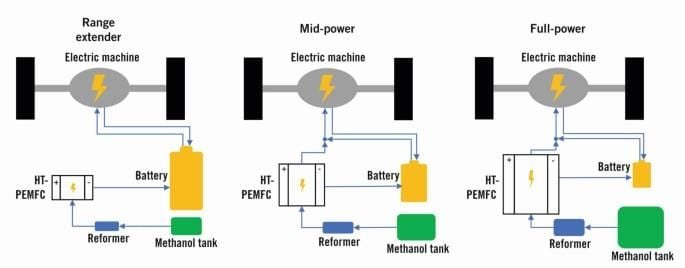

Electric tractors garnered interest over the last five years, but their limited runtime and refueling downtime curbed broader adoption, especially for high-demand seasonal tasks. That’s about to change, or at least so claim project collaborators. The newly unveiled Fendt e100 Vario Range Extender Concept harnesses liquid methanol—a renewable energy carrier formed by binding captured CO₂ with hydrogen—to generate a hydrogen-rich synthesis gas on-board; this feeds directly into high-temperature PEM (proton exchange membrane) fuel cells, delivering efficient electricity to recharge vehicle batteries during operation.

Here’s where it gets interesting: this design essentially doubles the work interval compared to conventional battery-only models with relatively trivial increases in machine weight. Many electric tractors manage only a few hours of operation before requiring lengthy recharges (sometimes eight hours or more), which constrains productivity on modern farms demanding continuous use during harvest or planting windows; yet with this system, prolonged operation aligns more consistently with expectations familiar from diesel workhorses. Topping up methanol is as swift as refueling diesel—only minutes lost instead of an entire shift evaporating while waiting at charging stations.

Methanol itself is not new in industrial circles—it boasts logistical merits rarely appreciated by lay audiences. Stored as a liquid at ambient pressure, it makes transportation and long-term storage unusually straightforward relative to compressed hydrogen alternatives and doesn’t require customized infrastructure beyond retrofitted diesel tanks already extant on most farms worldwide. Critics sometimes question whether upstream processes generating methanol from carbon capture truly result in negative lifecycle emissions; proponents counter that when sourced via renewable feedstocks and coupled with green hydrogen electrolyzers powered by wind turbines—or hydroelectric plants—the output can credibly achieve net-zero credentials (though absolute “zero” could be debated semantically).

In field demonstrations throughout Denmark and Germany last year—details of which emerged just recently—the prototype system demonstrated approximately two-fold increments in daily operating time on standard usage cycles compared against lithium-ion-only baselines from previous Fendt e100 electric tractor iterations. High electrical efficiency within these advanced HT-PEM stacks underpins those results: internal conversion rates regularly hit 50%+, markedly higher than many established combustion engine benchmarks hovering around 30-35%. However—and it must be acknowledged openly—PEM stack performance can fluctuate depending upon ambient temperature extremes found outside controlled laboratory settings.

Globally speaking, agricultural operations account for nearly 18% of all greenhouse gas emissions once machine activity is included alongside crop production cycles according to widely cited estimates published by environmental agencies over recent years—which further underscores how pivotal any propulsion overhaul may prove if agriculture targets its climate deadlines seriously rather than rhetorically waffling between aspirational slogans every year or two.

Among less-obvious advantages highlighted by AGCO engineers sits component durability: running clean-burning fuel cells theoretically erases much wear-prone residue associated traditionally with diesel exhaust particulates clogging sensitive aftertreatment hardware such as DPFs (diesel particulate filters) or SCR systems reliant upon urea injection technologies already imposed across several regulated markets since early 2010s mandates took effect—but still persisting concern revolves around long-term catalyst stability inside real-world farm environments filled necessarily not just with dust but volatile agrochemicals encountered daily under actual operational conditions; only time will tell whether theoretical longevity matches expectations set forth today.

Supply chains stand ready—or nearly so—for mass deployment because methanol can reuse almost all major distribution assets currently moving fossil fuels worldwide without demanding massive capital reinvestment: modularity that enables scalable rollouts even among smaller agri-cooperatives reluctant to risk budgets on untested storage formats would suggest lower barriers-for-entry versus pure-hydrogen strategies pitched sporadically elsewhere lately.

There exists chatter throughout engineering forums regarding possible auxiliary uses for waste heat generated from high-temp PEM cells integrated into ancillary thermal management circuits supporting either cab heating loads (certainly practical across cold Scandinavian fields) or potentially greenhouse warming applications—even though early-stage installations have focused primarily on drivetrain electrification alone so far; synergies seem evident should developers choose lateral expansion beyond traction-focused architectures someday soon if regulatory incentives align accordingly next fiscal cycle—that is unless legislative headwinds alter policy direction once again abruptly midstream as political landscapes are wont to do occasionally despite industry lobbying efforts maintaining consistent messaging otherwise since inception stages commenced late last decade!

Summing up somewhat circuitously—for no article perfectly traverses linear argument lines without meander—the methanol-based range extender marks a decisive step toward true decarbonization of heavy-duty agricultural platforms hitherto constrained largely by battery physics’ limitations rather than farmers’ ingenuity itself although certain questions linger unresolved at unveiling’s close regarding OPEX projections if global feedstock supply faces unexpected volatility later down the line unlike what forecasters modeled—but technological progress rarely unfolds along seamless timelines anyway, does it?