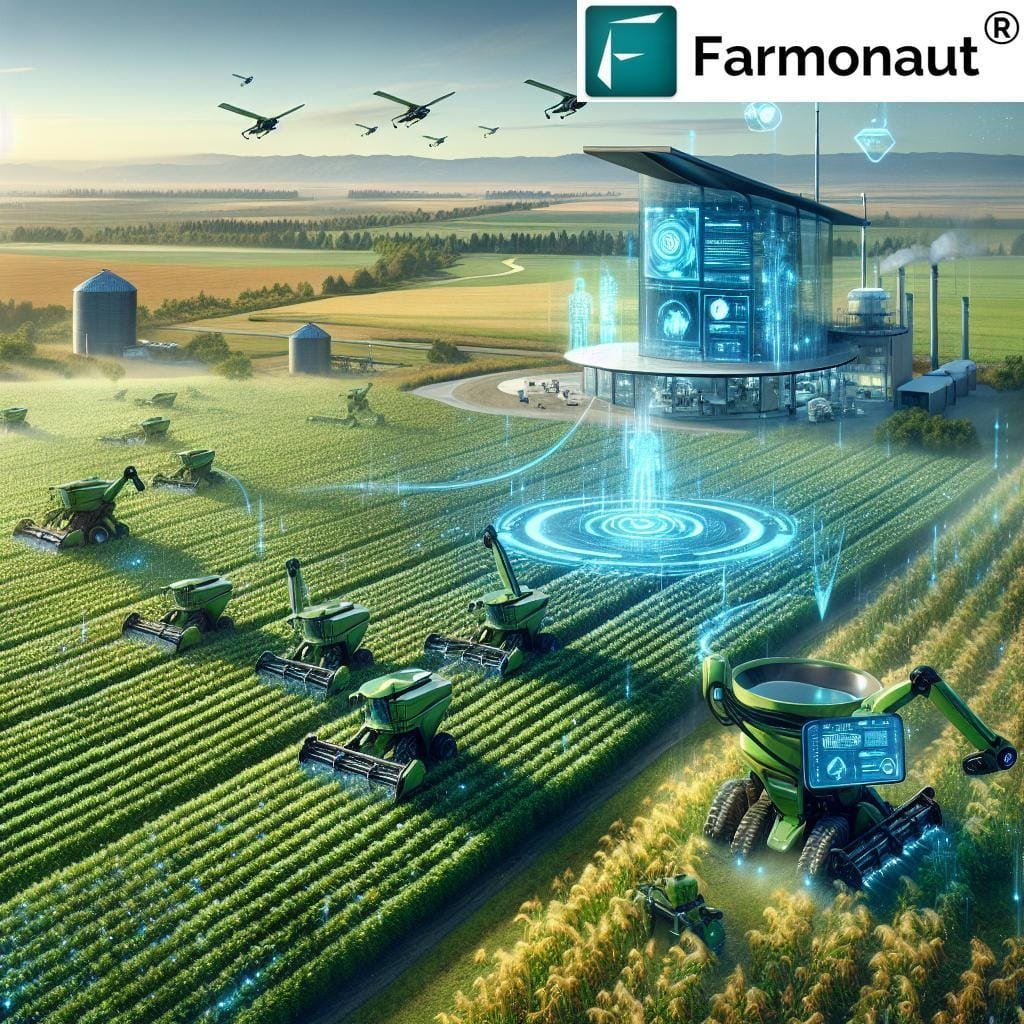

Agriculture stands at the cusp of a technological conversion as artificial intelligence reshapes traditional farming practices. From autonomous tractors to crop disease detection algorithms, AI applications are revolutionizing how farmers manage their operations. This technological shift promises increased efficiency and productivity, yet also raises critically important questions about implementation costs, data privacy, and the changing nature of agricultural work. As farms worldwide increasingly adopt smart technologies,understanding both the advantages and obstacles of AI integration becomes crucial for the future of agriculture. Artificial intelligence is reshaping modern agriculture, introducing unprecedented capabilities that streamline operations and boost productivity. Smart sensors deployed across fields continuously monitor soil conditions, moisture levels, and crop health, providing farmers with real-time data for informed decision-making. These technological advancements enable precise resource allocation,reducing waste and optimizing yield potential.

Machine learning algorithms analyze vast datasets to predict weather patterns, pest infestations, and optimal harvesting times. This predictive capability allows farmers to take proactive measures, protecting their investments and ensuring consistent crop production. AI-powered drones equipped with advanced imaging technology survey large areas efficiently, identifying problems that might go unnoticed through traditional monitoring methods.

Automated systems now handle routine tasks like irrigation, fertilization, and pest control with remarkable precision. These systems adjust their operations based on specific plant needs and environmental conditions, delivering resources exactly where and when they’re needed. The result is significantly reduced water consumption and chemical usage, making farming more environmentally sustainable.

However, the integration of AI in agriculture presents notable challenges.The initial investment required for implementing these technologies can be substantial, possibly excluding smaller farming operations. This creates a technological divide that could reshape the agricultural landscape, favoring larger, well-funded enterprises.

Training requirements pose another hurdle. Farmers and agricultural workers need to develop new skill sets to effectively operate and maintain AI-powered systems. This learning curve can be steep, particularly for those who have practiced traditional farming methods for generations.

Data security and privacy concerns emerge as farming operations become increasingly digitized. The collection and storage of sensitive agricultural data raise questions about ownership, access rights, and protection against cyber threats. Moreover,reliance on technology makes farming operations vulnerable to system failures or connectivity issues.

Compatibility between different AI systems and equipment from various manufacturers can be problematic. The lack of standardization in agricultural technology creates integration challenges and may limit the effectiveness of comprehensive farm management solutions.

Rural infrastructure limitations, including poor internet connectivity and inadequate power supply, can hamper the implementation of AI-based farming solutions. These technological constraints are particularly evident in developing regions where modern agriculture could have the most significant impact.

Despite these challenges, the potential benefits of AI in agriculture remain compelling. Increased efficiency, reduced environmental impact, and improved crop yields contribute to food security and sustainable farming practices. The technology continues to evolve, becoming more accessible and user-friendly, while addressing earlier limitations through improved design and functionality.

The agricultural sector stands at a pivotal point where traditional farming wisdom meets cutting-edge technology. Success lies in finding the right balance between leveraging AI’s capabilities while addressing implementation challenges and ensuring inclusive access to these transformative tools.