Now, as the sun scorches and combines hum across hemispheres, agriculturalists are witnessing a quiet but decisive reinvention. While seasoned farmhands might not gather around a tire in anticipation, this season’s developments show technology ticking forward just where Earth meets machine-on the rim.

A combine’s tires have quietly transformed from mere hoops of rubber to adaptive field specialists. In recent years-and more so at credible expos like Agrishow 2025-manufacturers rolled out advances that sometimes feel as foreign as quantum theory to older tractor operators. One detail that especially diverges from old habits: rubber tracks are being fitted onto high-powered harvesters with frequency now approaching ubiquity. These new configurations aren’t second-rate substitutes for wheels but stand-alone engineering achievements.

Unconventional Rubber Tracks Meet Evolving Farms

Consider Trelleborg’s ART1000 agricultural rubber track, debuting on South American soil with claims of both reducing soil stress during heavy field operations and increasing operational stability when cornering or handling hillside terrain. Rubber tracks historically belonged on earthmovers; yet fields stretching into rows against the Andes are becoming sites for such gear too.

As crops rotate and fall-planted grains emerge under unpredictable rains, these tracks demonstrate how legacy farming traditions mesh with networked technology-a subtle cognitive dissonance some practitioners note when they remember bouncing over ruts years ago in rigid-walled tires.

Another feature turning seed drills and self-propelled sprayers into intelligent actors is the TM150 CFO (Cyclic Field Operations) tire developed for heavyweight sprayers tackling long hours at inconsistent speeds. With its enlarged load-carrying ability during irregular pass patterns and highway transits between paddocks, this is less about brute survivability than responsive adaptation-increased flexion meaning less rutting even if things go south due to overnight rain.

Harvest Tire Trends Break Old Molds

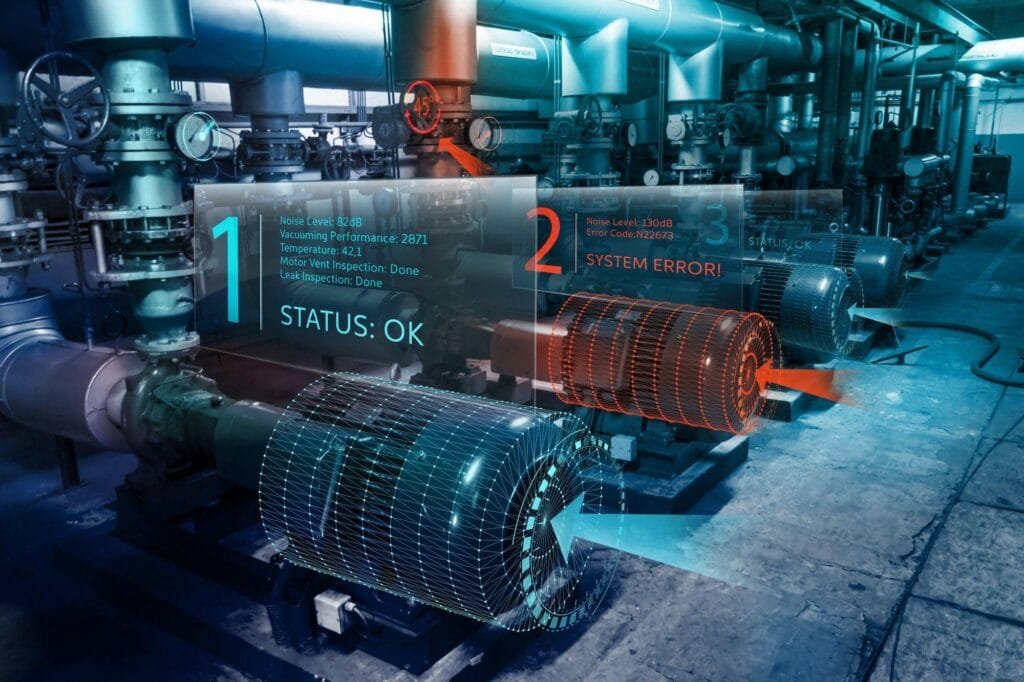

The pragmatic shift towards “smart” tire integrations could have been considered science fiction three decades past-tires fitted with sensors predicting wear patterns before a split appears on radial plies; systems monitoring air pressures that adjust dynamically while machinery lurches between beans stubble toward silage windrows.

But innovations transcend sensors alone. Contemporary tread designs mark departures from predictable straight-rib motifs which once dominated midwestern highways each September after harvest rushes began early due to frost advisories. Modern ‘R-1W’ treads deliver grippier-yet-gentler imprints underfoot-a contradiction which only makes sense knowing how much yield rides atop every uncompressed square inch of topsoil.

It’s counterintuitive perhaps: more aggressive surface geometry produces softer outcomes underground because contact patches distribute weight broadly instead of trench-like ruts which can stick around painfully long after an axle passes by.

Meanwhile, manufacturers like Mitas push further by tuning sidewall responses specific for Cyclic Field Operations-a phrase surely dreamed up in some conference room but one carrying actual weight for tractors tasked with stop-start cycles across irregularly-shaped plots during unpredictable weather windows. CFO-tech engineered compounds endure varying loads without registering overstressed wear signatures common among previous generations hauled hastily along rural blacktops.

Crop specialists may argue whether these improvements outpace mechanical advances delivered by satellite-controlled planters or remote-sensing sprayer drones-it depends whom you ask over coffee in main street diners crisscrossing wheat country anyway-but consensus seems harder than ever nowadays since opinions grow wild as hedge bindweed amid precision rows.

Unexpected Impacts Down the Road (Sometimes Literally)

Tire transformations didn’t strictly evolve linearly alongside drivetrain innovations; often were reactions to sudden shifts elsewhere-regulatory demands concerning road transit limits or abrupt decreases in traditional tillage practices led engineers back into their labs late at night tracing sidewall stress curves under oddball loading scenarios nobody predicted decades ago. Some say sustainability considerations forced everyone’s hand sooner than initial market surveys implied; others maintain it was simply customer feedback echoing louder through digital channels threaded throughout global equipment markets nowadays.

Despite clear evidence supporting longer service intervals thanks largely to improved compound durability topped by smart inflation modulation systems working alongside variable rate seeding implements-the swift decline of blowouts has not been quite so pronounced everywhere yet (an awkward truth buried beneath glossy product launches). However, most agree margins are thinning not just within spreadsheets but right out there where wheat finally stands ready for augers come twilight hour rushes-and reliable traction matters most while headlights cut through autumn fogbanks old timers recall fondly if you press them enough at county fairs anyhow.

Casting Forward Yet Glancing Back

There is an inherent tension visible when discussing progressive agri-tire trajectories: nostalgia battling necessity. Agricultural shows headline words like “sustainability” next to innovative bead profiles boasting patent-pending grip characteristics-all part marketing showcase but partially genuine response too. One might find curious combinations popping up-like increased reliance on mixed-material rims even before mainstream demand truly solidifies justification beyond simple cost efficacy calculations evidenced only sporadically so far.

Perhaps that’s why no one bats an eyelash anymore if someone compares new-generation harvester wheels favorably against ice skates gliding across thin pond surfaces come February thaw rather than reliably referencing well-worn tractor metaphors-which always seemed quaint considering their slow clamber toward progress anyway.