In a notable leap forward for agricultural automation, John Deere has unveiled its newest generation of autonomous farming equipment, marking another milestone in the evolution of precision agriculture.These self-driving solutions integrate advanced GPS technology, machine learning algorithms, and refined sensor systems to perform complex farming operations with minimal human intervention.As global farming faces increasing pressure to maximize efficiency while addressing labor shortages, these autonomous systems represent a practical response to modern agricultural challenges.Agricultural technology takes a significant leap forward with the introduction of advanced autonomous solutions from the industry leader in farm equipment. The new lineup integrates artificial intelligence, machine learning, and precision agriculture to revolutionize farming operations across diverse landscapes.

The latest autonomous tractor systems feature enhanced GPS guidance with accuracy down to 2.5 centimeters, enabling precise field operations without human intervention. these machines can work around the clock, maximizing productivity during crucial planting and harvesting seasons. The upgraded sensor suite includes LiDAR, cameras, and radar systems that work in tandem to detect obstacles, analyze field conditions, and make real-time adjustments to equipment settings.

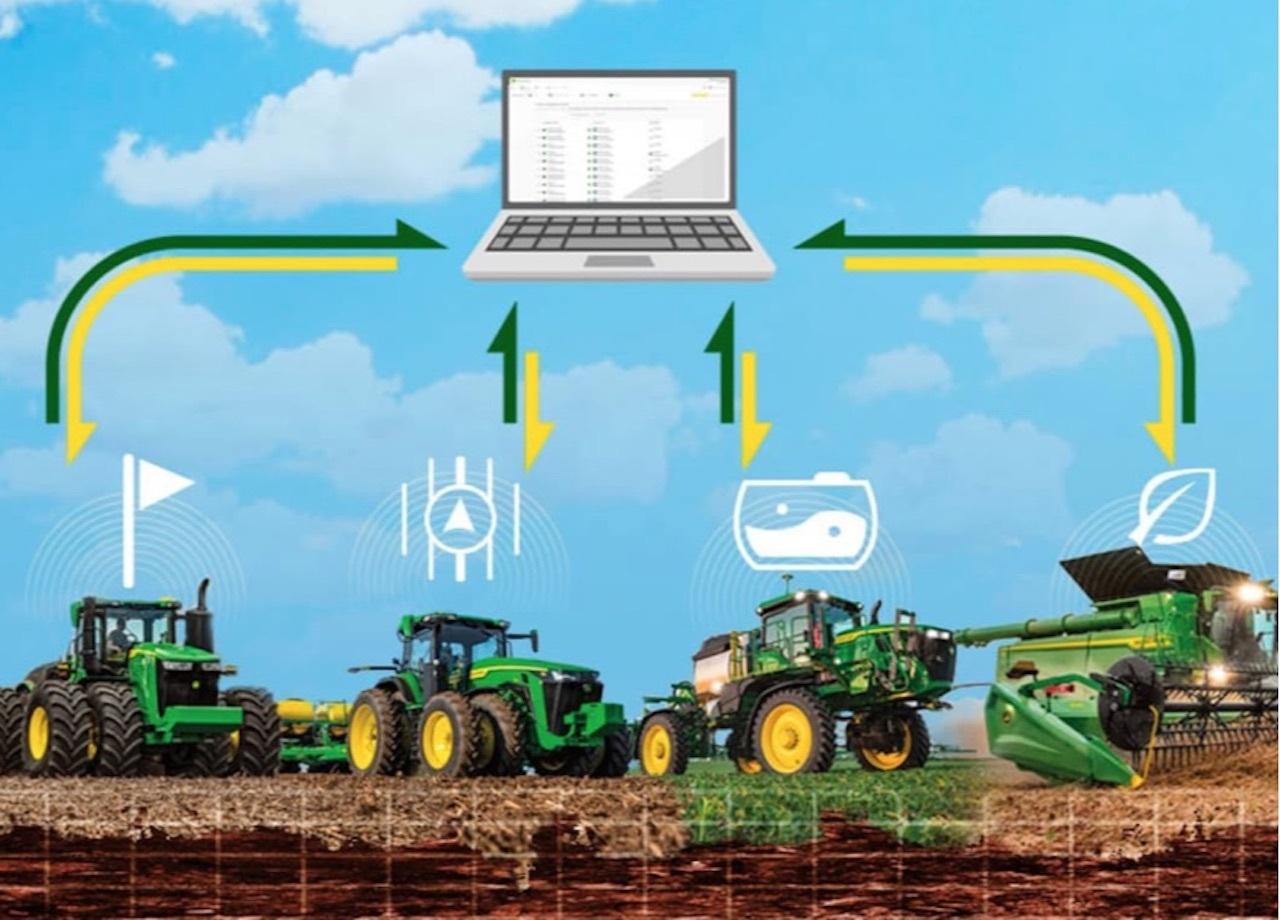

Farmers can now manage entire fleets of autonomous equipment through a sophisticated mobile interface, allowing them to monitor operations, adjust parameters, and deploy machines with simple touch commands. The system’s artificial intelligence continuously learns from operational data, optimizing routes and resource usage while reducing waste and environmental impact.

A standout feature is the advanced crop monitoring system that uses computer vision to identify plant health issues, pest infestations, and irrigation needs. This technology enables targeted interventions, reducing the use of pesticides and water while maximizing yield potential. The autonomous spraying system precisely applies chemicals only where needed, cutting costs and promoting environmental sustainability.

The new AutoLoad feature enables combines to coordinate with autonomous grain carts,optimizing harvest logistics without operator intervention. This synchronization extends to the entire harvest chain, from field operations to storage facility delivery, streamlining the entire process.

Weather integration capabilities allow the autonomous system to adapt to changing conditions automatically.Machines can independently decide to continue, modify, or pause operations based on real-time weather data and forecasts, protecting both equipment and crops.Remote diagnostics and predictive maintenance alerts help prevent downtime by identifying potential issues before they become critical. The system schedules maintenance windows during optimal times, ensuring maximum uptime during crucial farming periods.

Security features include advanced encryption protocols and geofencing capabilities, protecting both the physical equipment and operational data. Multiple redundancy systems ensure safe operation, with various fallback modes and emergency protocols in place.

The implementation of machine-to-machine dialogue enables seamless coordination between different equipment types, creating an efficient ecosystem of autonomous farm operations. This interconnected network optimizes resource allocation and reduces operational bottlenecks.

These autonomous solutions are scalable, accommodating both small family farms and large agricultural operations. The modular design allows farmers to gradually integrate autonomous features into their existing equipment fleet, providing a flexible pathway to automation that aligns with their operational needs and budget constraints.