A new retrofitting solution has entered the agricultural technology market, offering farmers the ability to transform their existing machinery into autonomous equipment. The upgrade kit, designed to integrate with standard tractors and implements, represents a middle-ground approach between customary farming methods and the purchase of entirely new autonomous vehicles. This growth addresses the growing demand for automation in agriculture while considering cost-effectiveness and the practical needs of farming operations. A groundbreaking agricultural solution has emerged in the form of a extensive retrofit kit that transforms traditional farming equipment into autonomous machines. The technology, developed by AgriTech Solutions, enables farmers to upgrade their existing machinery rather than investing in entirely new autonomous vehicles.

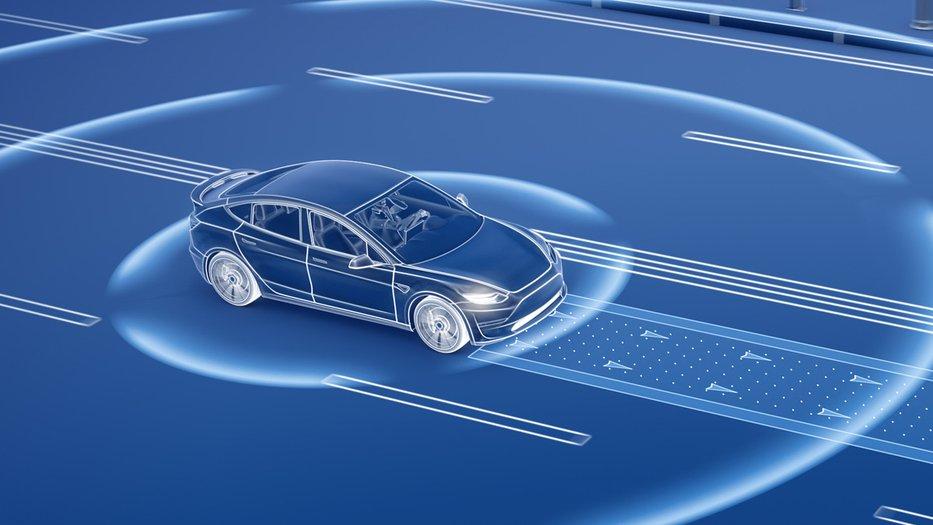

The conversion system includes advanced GPS guidance, computer vision cameras, proximity sensors, and a central processing unit that integrates seamlessly with most tractors and harvesters manufactured after 2010. This modular approach substantially reduces the financial barrier to automation, with the kit priced at approximately one-fifth the cost of new autonomous equipment.

Installation requires minimal technical expertise and can be completed within a day. The systemS primary components mount onto predetermined points on the vehicle, while the control interface connects to the existing operational framework. Farmers maintain full manual override capabilities, ensuring safety and compliance with current agricultural regulations.

The technology utilizes machine learning algorithms to optimize field operations,including planting,fertilizing,and harvesting. Real-time data collection through integrated sensors enables precise resource management and improved yield forecasting. The system adapts to various weather conditions and can operate effectively during both day and night.Field trials conducted across diverse agricultural environments demonstrated a 30% reduction in operational costs and a 25% increase in precision compared to traditional farming methods. The autonomous capabilities allow for extended working hours without operator fatigue, particularly beneficial during critical planting and harvesting windows.

Environmental benefits include reduced soil compaction through optimized path planning and decreased chemical usage through precise application methods. The system’s efficiency improvements result in lower fuel consumption, contributing to both cost savings and reduced environmental impact.

Security features incorporate geofencing technology, remote shutdown capabilities, and encrypted communications to protect against unauthorized access or operation.Regular over-the-air updates ensure the system maintains current security protocols and performance optimizations.

The kit’s monitoring interface provides real-time operation data through a mobile application, allowing farmers to supervise multiple vehicles simultaneously from any location with internet connectivity. Custom field boundaries,obstacle mapping,and operation parameters can be programmed through the same interface.

Support services include a 24/7 technical assistance hotline, remote diagnostics, and a network of certified installation partners across major agricultural regions. The manufacturer offers a three-year warranty covering both hardware and software components, with extended coverage options available.

Initial market response indicates strong interest from medium to large-scale farming operations, with pre-orders exceeding first-quarter production capacity. Industry analysts project rapid adoption rates as farmers seek cost-effective automation solutions amid rising operational expenses and labor shortages.

The innovation represents a significant step toward accessible agricultural automation, potentially reshaping the industry’s approach to technology adoption and operational efficiency.