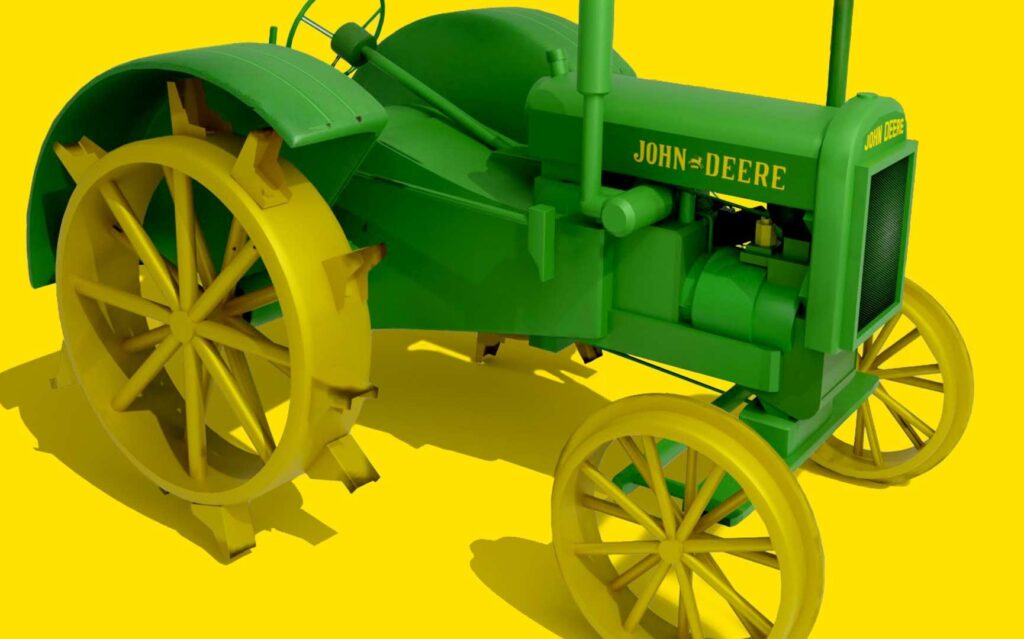

Agricultural automation takes a meaningful step forward with FarmX’s latest innovation in tractor technology. The company’s new retrofit kit promises to transform existing specialty tractors into autonomous vehicles, offering a practical solution for farmers who want to modernize their current equipment without purchasing entirely new machinery. This growth addresses the growing need for automated farming solutions in specialty crop operations, where customary autonomous vehicles have faced implementation challenges. The agricultural technology company has developed an innovative retrofit solution that transforms existing specialty tractors into autonomous farming machines. This groundbreaking system enables farmers to automate their current fleet without investing in entirely new autonomous equipment.The retrofit kit consists of refined sensors, advanced control systems, and precision actuators that can be installed on most specialty tractor models. These components work together to enable autonomous operation while maintaining the tractor’s original functionality for manual use when needed.

Central to the system’s capabilities is its sensor array, which includes LiDAR, cameras, and GPS technology. This comprehensive sensing package allows the automated tractor to navigate fields with centimeter-level accuracy while detecting and avoiding obstacles in real-time. The system’s artificial intelligence processes this sensory data to make informed decisions about path planning and implement control.

Farmers can control and monitor their automated tractors through a user-friendly mobile application. The interface provides real-time data on operation status, field coverage, and machine health. Multiple tractors can be managed simultaneously, increasing operational efficiency and reducing labor requirements.

The retrofit solution is especially valuable for specialty crop operations, where precise navigation between narrow rows and careful implement control are essential. The system’s advanced algorithms ensure consistent spacing and depth control for various farming operations, from spraying to cultivation.

Installation of the retrofit kit typically takes less than a day and can be performed by certified technicians. The modular design allows for easy maintenance and updates, ensuring the system remains current with technological advances. The company provides comprehensive training and support to help farmers maximize the benefits of their automated equipment.

Field trials have demonstrated significant improvements in operational efficiency, with automated tractors working up to 20 hours per day while maintaining precise accuracy.This extended operating window helps farmers complete critical tasks during optimal weather conditions and tight seasonal windows.

Safety features include redundant emergency stop systems, geofencing capabilities, and remote shutdown options. The automated tractors continuously monitor their surroundings and automatically halt operations if unexpected obstacles or conditions are detected.

The solution addresses the growing labor challenges in agriculture while providing a cost-effective path to automation. Farmers can preserve their investments in existing equipment while gaining the benefits of autonomous operation. The system’s scalability allows operations to gradually transition to automation based on their needs and resources.

The retrofit technology represents a significant step forward in agricultural automation, making advanced autonomous capabilities accessible to a broader range of farmers. By focusing on specialty crop applications, the system addresses a crucial market segment where precision and reliability are paramount for triumphant operations.