Agricultural machinery giant John Deere has unveiled its latest autonomous farming fleet, marking a critically important shift in the industry’s approach too farm automation. The new line of self-driving tractors and harvesters combines AI-powered navigation systems with precision farming technology, allowing farmers to operate multiple vehicles concurrently without direct human intervention. This launch represents the company’s largest investment in autonomous technology to date, building upon their existing driver-assistance features to deliver fully autonomous capabilities across their main equipment categories. in a groundbreaking growth for agricultural technology,the latest autonomous farming fleet has emerged from the renowned manufacturer’s innovation hub. The comprehensive lineup features tractors, harvesters, and specialized equipment that operate with minimal human intervention, marking a significant shift in modern farming practices.

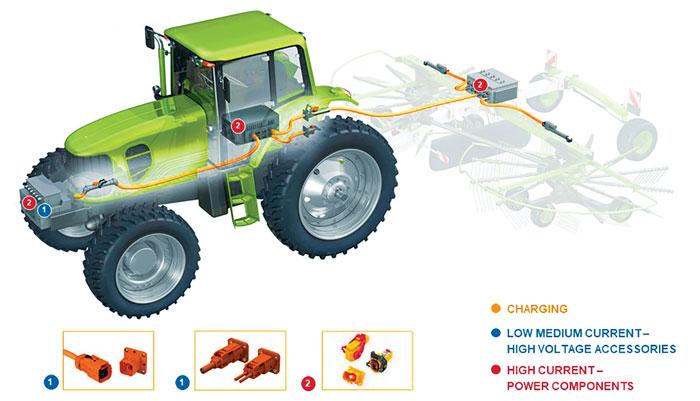

These state-of-the-art machines utilize advanced GPS technology, machine learning algorithms, and an array of sensors to navigate fields with precision accuracy up to 2.5 centimeters. The fleet’s artificial intelligence system processes real-time data from multiple sources, enabling vehicles to adjust their operations based on soil conditions, crop health, and weather patterns.Each vehicle in the autonomous fleet is equipped with obstacle detection systems and emergency shutdown protocols, ensuring safety during operation. The machines communicate with each other through a secure network, coordinating movements and sharing critical information to optimize field coverage and minimize resource waste.

Farmers can monitor and control the entire fleet through a centralized dashboard accessible via smartphone, tablet, or computer.The interface provides detailed analytics on equipment performance, fuel efficiency, and operational status.Remote diagnostics capabilities allow technicians to identify and resolve potential issues before they affect productivity.

The autonomous system’s precision farming capabilities extend beyond basic navigation. These machines can automatically adjust seeding rates, fertilizer application, and harvesting parameters based on soil composition and crop requirements. This level of customization helps maximize yield while minimizing input costs.

Environmental sustainability features prominently in the design. The fleet’s electric-hybrid powertrains reduce carbon emissions while maintaining the power needed for demanding agricultural tasks. Smart resource management systems optimize water usage and minimize chemical applications through targeted distribution methods.

Field testing has demonstrated a 20% increase in operational efficiency compared to conventional farming methods. The autonomous fleet can work around the clock in various weather conditions,addressing the growing challenge of labor shortages in agricultural regions.

Data security measures include encrypted communications and regular software updates to protect against potential cyber threats. The manufacturer has established a dedicated support network to provide technical assistance and training to farmers transitioning to autonomous operations.

The fleet’s modular design allows for future upgrades and compatibility with existing farming equipment, providing a flexible solution for various farm sizes and types. Integration with popular farm management software ensures seamless incorporation into current agricultural operations.

Initial deployment will focus on large-scale grain operations, with plans to expand into specialty crop applications. The manufacturer has partnered with leading agricultural universities to gather performance data and refine the system’s capabilities across different farming environments and challenges.

Pricing reflects the advanced technology incorporated into each unit,with flexible financing options available to help farmers manage the transition to autonomous operations. The manufacturer estimates a return on investment period of three to five years, factoring in reduced labor costs and improved operational efficiency.