The global electric farm tractor market has entered a transformative phase in 2024,driven by increasing environmental concerns and technological advancements in agricultural machinery. This comprehensive study examines the current state of electric tractor adoption,market dynamics,and future growth prospects across major agricultural regions. As conventional diesel-powered tractors face scrutiny over emissions and operating costs, manufacturers are developing innovative electric alternatives that promise reduced environmental impact while maintaining operational efficiency. The analysis encompasses market trends, key players, technological developments, and regulatory frameworks shaping the industryS evolution.The agricultural sector is witnessing a transformative shift towards enduring farming practices, with electric farm tractors emerging as a cornerstone of this evolution. Market analysis reveals a compound annual growth rate of 12.8% for the electric farm tractor industry, driven by increasing environmental consciousness and governmental support for clean energy initiatives.

Key manufacturers have intensified their research and progress efforts, focusing on battery technology advancement and power optimization. Current models offer operational capacities ranging from 4 to 8 hours on a single charge, with rapid charging capabilities that minimize downtime. Industry leaders like John Deere, Kubota, and Solectrac have expanded their electric tractor portfolios, introducing models with power outputs varying from 30 to 100 horsepower.

European markets lead the adoption curve, with Norway and Germany showing the highest penetration rates. This trend is attributed to robust infrastructure support and substantial government incentives for electric agricultural equipment. The Asia-Pacific region demonstrates notable growth potential, particularly in India and China, where agricultural modernization initiatives align with environmental goals.

Technical innovations in 2024 include enhanced power management systems,regenerative braking mechanisms,and smart farming integration capabilities. Manufacturers are incorporating IoT sensors and GPS technology, enabling precise field operations and real-time performance monitoring. Battery technology improvements have resulted in higher energy density and extended service life, addressing previous limitations in operational duration.

Cost considerations remain a critical factor, with electric tractors commanding a 30-40% premium over conventional models. However, analysis shows that total ownership costs achieve parity within 5-7 years, considering reduced maintenance requirements and lower operating expenses. Government subsidies in various regions further improve the economic proposition for farmers transitioning to electric equipment.

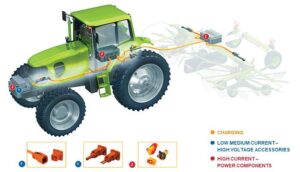

Infrastructure development poses both challenges and opportunities. The industry is witnessing increased investment in charging networks specifically designed for agricultural applications. Solar-powered charging stations are gaining traction, particularly in remote farming locations where grid connectivity is limited.

Market segmentation reveals varying demands across different farm sizes. Small to medium-sized operations show stronger adoption rates for compact electric tractors, while larger farms are gradually incorporating high-capacity models for heavy-duty applications. Specialized versions for vineyard operations and greenhouse farming have also emerged,demonstrating the industry’s adaptability to diverse agricultural needs.

environmental impact assessments indicate that electric tractors reduce carbon emissions by approximately 78% compared to diesel alternatives when charged from renewable sources. This significant reduction aligns with global agricultural sustainability goals and carbon neutrality targets set for 2050.

supply chain dynamics have evolved with increased localization of component manufacturing, particularly in battery and electric drivetrain production. This shift has improved cost efficiency and reduced dependency on international suppliers, contributing to market stability and product availability.