The landscape of modern agriculture is undergoing a significant transformation with the emergence of autonomous technologies. While conventional tractors have been the backbone of farming operations for decades, a new generation of small, specialized field robots is challenging their dominance. This shift raises questions about the relative merits of traditional tractor-based automation versus nimble field bots in addressing contemporary agricultural challenges such as labor shortages, sustainability demands, and precision farming requirements. The landscape of modern farming is undergoing a dramatic transformation with the emergence of two distinct technological approaches: traditional automated tractors and innovative field robots. While both solutions aim to enhance agricultural efficiency, they serve different purposes and offer unique advantages.

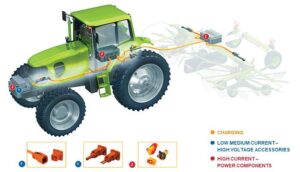

Traditional tractors, now equipped with autonomous capabilities, excel at handling large-scale operations across vast farmlands. These machines maintain the familiar form factor of conventional tractors while incorporating elegant GPS guidance systems, precision steering, and automated implement control. They effectively manage tasks like plowing, planting, and harvesting on industrial-scale farms, covering extensive acreage with minimal human intervention.

Field robots, in contrast, represent a departure from the conventional farming paradigm. These smaller, nimbler units operate in swarms or individually, navigating between crop rows with unprecedented precision. Their compact design allows them to work in confined spaces and perform targeted interventions at the individual plant level. These bots excel at tasks like selective weeding, precise fertilizer application, and detailed crop monitoring.

cost considerations play a crucial role in the implementation of these technologies. Autonomous tractors require ample initial investment but can efficiently manage large operations with reduced labor costs. Field robots, while potentially less expensive per unit, may require multiple units to cover the same area as a single tractor.though, their ability to work continuously and perform specialized tasks frequently enough justifies the investment for certain agricultural operations.

Environmental impact represents another key differentiator. field robots typically have a lighter footprint, causing minimal soil compaction and often running on electric power, reducing emissions. Autonomous tractors, while more efficient than their manual counterparts, still contribute to soil compression and typically rely on conventional fuel sources.

The choice between these technologies often depends on specific farming needs. Large-scale grain operations benefit from autonomous tractors’ ability to handle heavy implements and cover extensive areas quickly. Specialty crop farms and organic operations frequently enough find field robots more suitable due to their precision in pest management and ability to minimize chemical usage.

Data collection capabilities vary between the two approaches. Field robots excel at gathering detailed, plant-level details, creating extensive maps of crop health, soil conditions, and pest presence. Autonomous tractors typically focus on broader data collection, such as yield mapping and soil composition analysis across larger areas.

Maintenance requirements differ significantly. Autonomous tractors share many components with traditional machines, making repairs familiar to existing maintenance teams. Field robots often incorporate more specialized technology, potentially requiring new expertise for upkeep, but their modular design can simplify component replacement and upgrades.